Case Study | Application of Microseismic Monitoring in Shale Gas Fracturing

Jun 06,2025

Location: Hanzhong, Shaanxi

Task: microseismic crack monitoring

Time: 2024.1.10-2024.1.15

Weather: sunny to cloudy

Equipment: UGL-3C

Parameters: 120 4G node seismometers are evenly arranged above the fracturing section with a 200m grid

Field Picture:

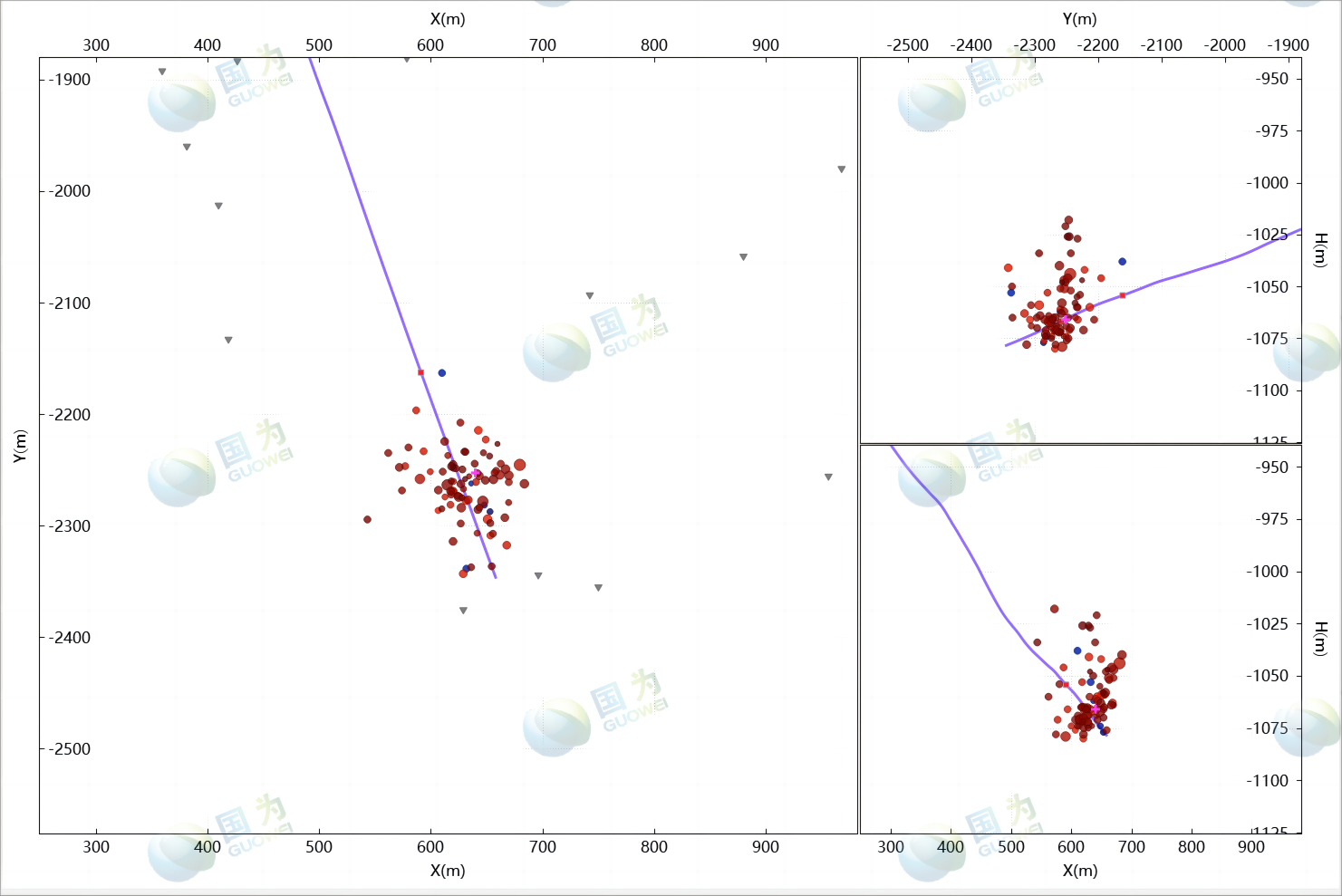

Seismic Result:

The ground microseismic monitoring signal was clear and the energy was concentrated, so high-quality monitoring data of the underground fracture network was obtained. Through monitoring positioning and result analysis, high-precision parameters of the fracture network were obtained, and data such as fracture length, width, height and overall transformation volume were obtained, verifying the scientificity and effectiveness of the overall process of fracturing construction.

The first fracture was 212m long, 61m wide, 11m high, and 4.487e+06m^3 in transformation. Real-time monitoring of fracturing found that the event point first occurred near the wellbore, where the event points were dense, and then extended to both sides of the wellbore. The extension distances on the northeast and southwest sides were similar, and there were no other obvious abnormalities. The main event depth was -1070 to -1060m.

The second fracture was 196m long, 53m wide, 10m high, and 2.049e+06m^3 in transformation. Real-time monitoring of fracturing shows that the event point first occurs near the wellbore, where the event points are dense, and then extends to both sides of the wellbore. The extension distance between the north and south sides is slightly smaller than that between the west and east sides. There are no other obvious abnormalities. The main event depth is -1063 to -1052m

BLOG

CONTACT

Tel: 0086-0551-65327898 / 65327899

Fax: 0086-0551-65327899

E-mail: hfgwe@hfgwe.com

Add: 9th Floor, Building A, G3, Phase II, Innovation Industry Park,No. 2800 Innovation Avenue, High-tech Zone, Hefei city,Anhui Province, China

Mobile website

Hefei Guowei Electronics Co., Ltd.

Subscribe Us

We will contact you within one working day. Please pay attention to your email.

CopyRight:Hefei Guowei Electronics Co., Ltd. Powered by 300.cn SEO